F.A.Q. à l'usage des futurs conserveurs professionnels

Qu'est-ce que la pasteurisation ?

C'est un procédé pour la conservation des aliments par lequel un aliment est chauffé à une température définie pendant une période de temps définie avant d'être refroidi rapidement.

La pasteurisation réduit de façon significative le nombre de micro-organismes dans le produit pasteurisé, mais certaines formes pathogènes résistent (comme les spores). C'est pourquoi il est important de maintenir au frais les aliments pasteurisés afin de prévenir la multiplication des bactéries qui n'ont pas été détruites.

La pasteurisation diffère du procédé U.H.T. utilisé pour le traitement du lait où la chaleur seule joue un rôle dans la destruction des micro-organismes.

Qu'est-ce que la stérilisation ?

C'est une technique destinée à éliminer tout germe microbien d'une préparation en la portant à haute température (+ de 100°C) pendant une période définie selon le produit traité avant d'être refroidi rapidement.

Qu'est- ce que la conserve ?

La conserve ou appertisation est une méthode de préservation des aliments qui consiste à les mettre dans récipients (boites ou bocaux) que l'on rend étanches à l'air et que l'on chauffe ensuite pour détruire les micro-organismes contaminants. Les températures à atteindre suivant les produits fabriqués se situent entre 110 et 120°C.

Les aliments que l'on peut mettre en conserve en les soumettant haute température sont les légumes, les viandes, les fruits de mer, les volailles, les produits laitiers.

Les seuls aliments qui peuvent être mis en conserve dans un bain d'eau bouillante sont ceux qui sont naturellement acides comme les fruits, certains légumes (cornichons, par exemple) ou d'autres auxquels on a ajouté un acidifiant (vinaigre), ou de l'huile ou de l'alcool.

Une conserve bien faite, en appliquant les barèmes adéquats à chaque produit permet une conservation longue durée sans contrainte de réfrigération, c'est-à-dire qu'elle peut être stockée à température ambiante.

Qu'est-ce que la mise sous vide ?

C'est une technique qui réduit la quantité d'air donc l'action de l'oxygène dans un emballage.

Ce n'est, en aucun cas, une technique de conservation ; il faut la considérer - au mieux - comme une méthode de prolongation de la vie d'un produit frais dans un milieu réfrigéré à température basse constante. Le non respect de cette disposition pourrait entraîner des conséquences fâcheuses pour la santé.

Techniques de stérilisation et pasteurisation :

La seule formule acceptée - en principe - par les services d'hygiène est l'utilisation d'un stérilisateur autoclave conforme aux normes en vigueur estampillé CE .

Qu'est-ce qu'un autoclave ?

Un autoclave est un récipient à parois épaisses et à fermeture hermétique conçu pour réaliser sous pression (de quelques bars) la cuisson ou la stérilisation à la vapeur d'eau ou à l'eau.

On appelle autoclavage un cycle d'utilisation d'un autoclave et autoclaver est le verbe.

En quoi consiste l'équipement obligatoire d'un autoclave destiné à la fabrication de conserves ?

La directive européenne (DESP 97/23/CE) demande à ce que chaque appareil soit équipé :

- d'un thermomètre à lecture

- d'un thermomètre enregistreur ou tout autre procédé d'enregistrement permettant de vérifier le cycle de stérilisation

- d'un manomètre permettant de contrôler la pression

- d'un système de refroidissement afin de procéder au refroidissement immédiat de la conserve.

Alimentation/ énergie des autoclaves :

Nos autoclaves KORIMAT peuvent être alimentés en électricité, gaz ou fioul (pour les 240 litres)

Nous vous donnons, à titre indicatif, les consommations pour chaque capacité :

a) Korimat 120 litres :

- Eau

- Electricité

- 380 triphasé - 9 kwh

b) Korimat 240 litres :

- Eau

- Gaz naturel : 3 m³/h - Gaz liquéfié : 1 m³/h

- Électricité

- Fuel : environ 2 kg/h

Contrôles récurrents :

Tout propriétaire d'un autoclave doit se conformer aux contrôles suivants :

- Tous les deux ans, visite intérieure et extérieure de la cuve par un organisme certifié

- Tous les dix ans, contrôle complet et ré-épreuve par un organisme certifié (sinon, l'autorisation d'exploitation peut devenir caduque)

Quelle forme d'énergie choisir ?

Vous êtes, bien sûr, libre du choix de votre énergie et nous savons qu'en certains lieux, il n'y parfois qu'une possibilité.

Cependant, nous nous permettons de vous conseiller d'utiliser l'électricité pour plusieurs raisons :

- Facilité d'installation , beaucoup moins de contraintes que pour le gaz et le fioul, pas de nécessité de ventilation haute et basse

- Pas de chaleur intempestive dans le laboratoire.

- Possibilité de programmer votre appareil pour un usage nocturne à tarif réduit.

Quelle capacité d'autoclave choisir ?

Là est la question.

Mais le choix, chez nous, est limité, volontairement.

4 capacités : 60 litres, 120 litres, 240 litres ou 380 litres.

Il vous faut déterminer le nombre de bocaux à traiter en une fois et leur capacité.

Dans un autoclave 120 litres, vous pouvez, par exemple, stériliser :

- 110 bocaux de 250 g

- 45 bocaux de 950 g

Dans un autoclave de 240 litres, vous pouvez, par exemple, stériliser :

- 220 bocaux de 250 g

- 90 bocaux de 950 g

Quid des barèmes de stérilisation :

Chaque conserve appelle un barème temps/température. Appelez-nous, nous en discuterons avec vous.

Peut-on réchauffer un bocal au micro-onde ?

En règle générale, non, ...mais le bocal Weck, sans élément métallique après stérilisation, vous permet sans souci aucun, de faire réchauffer votre bocal au micro-onde : facilité, gain de temps, gain d'énergie! Toutefois, n'oubliez pas de l'ouvrir avant de le passer au micro-onde.

Comment puis-je m'assurer que ma conserve est bien stérilisée?

Lorsque un produit est correctement stérilisé dans un bocal Weck, la languette extérieure est positionnée vers le bas ; c'est une phase visuelle et efficace de constater d'un simple coup d'œil si votre conserve est parfaitement réussie.

D'autres questions ?

N'hésitez pas à nous appeler, nous nous ferons un plaisir de vous répondre.

Appelez-nous ou envoyez-nous un e-mail à strasbourg@conservor.fr

F.A.Q. sur la stérilisation domestique

En quoi diffère la stérilisation domestique de la stérilisation professionnelle ?

La ménagère ne dispose généralement pas d'un stérilisateur autoclave pour confectionner ses conserves ; elle utilise, soit une « lessiveuse » à l'ancienne, soit un stérilisateur ménager. Avec ces appareils, la température maximum atteinte est de 100°C.

L'élément déterminant pour une bonne conserve sera donc le temps de stérilisation. Il faudra prolonger ce temps afin de détruire le maximum de bactéries, champignons et micro-organismes.

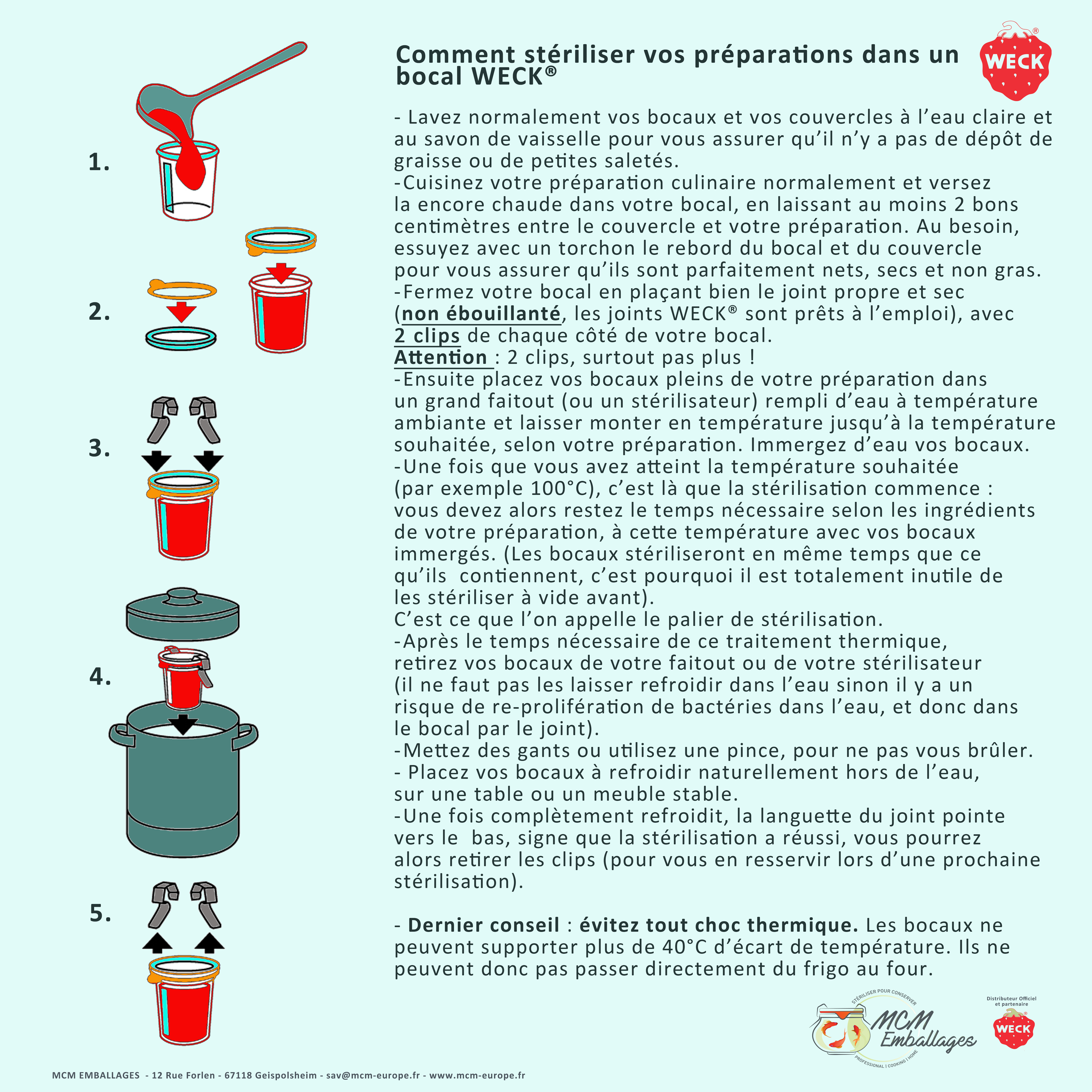

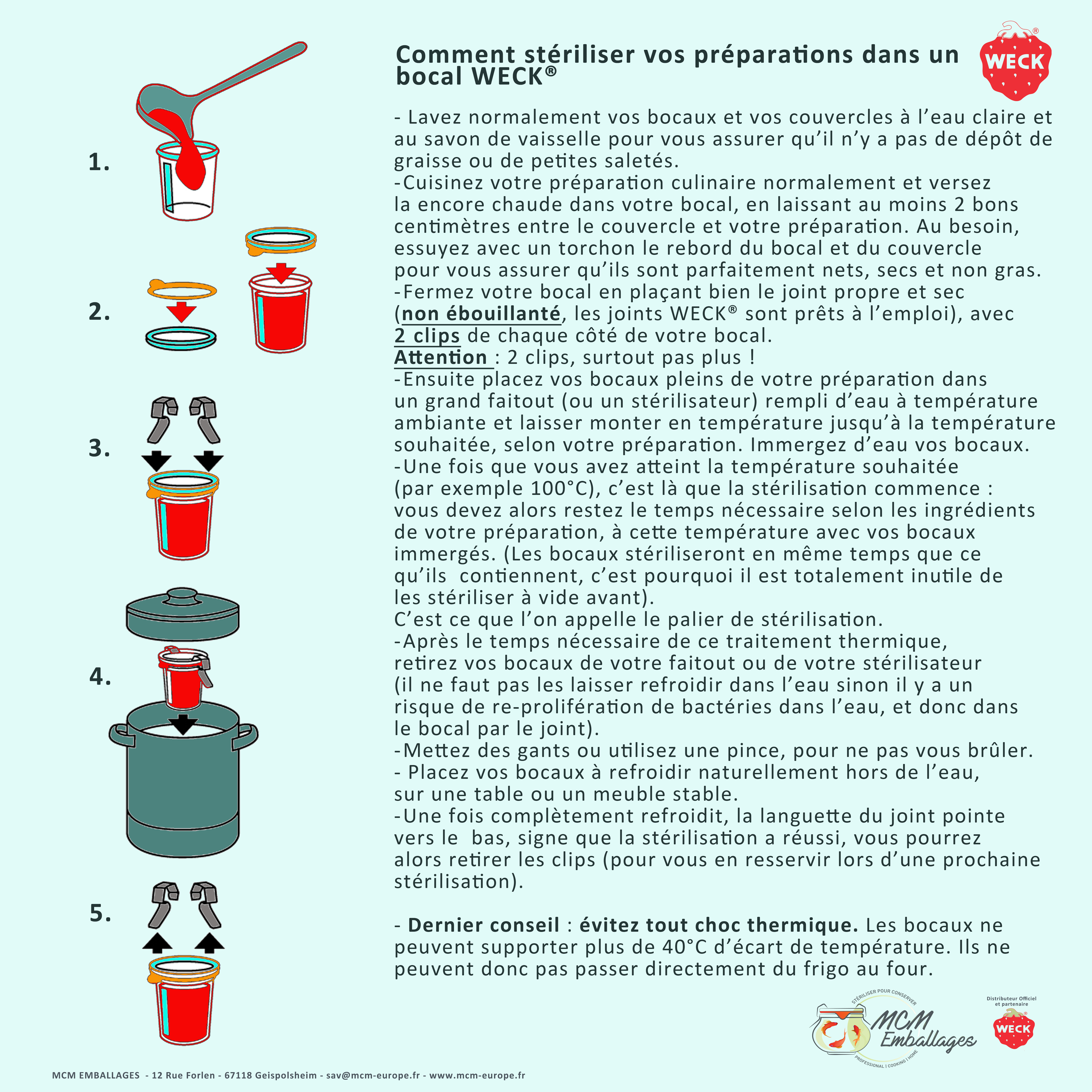

Comment bien placer les bocaux dans un stérilisateur domestique?

C'est très simple ! Respectez simplement les indications du dessin ci dessous :

Quelles précautions prendre pour confectionner une bonne conserve ?

Tout d'abord, de bons produits !

Ensuite, une hygiène parfaite. des bocaux, couvercles et joints propres.

Enfin, respecter les temps de stérilisation.

Peut-on tout stériliser ?

Oui : viandes, gibiers, pâtés, rillettes, gibiers, foies gras, légumes, fruits, potages, compotes, confitures et même des gâteaux....

Doit-on « stériliser » les bocaux avant un cycle de stérilisation de produits ?

NON ! Ceci est une hérésie véhiculée depuis fort longtemps dans les recettes de « grand-mère » ; un minimum de réflexion vous porte à constater que les bocaux n'ont pas à subir une stérilisation avant d'être remplis. Quand bien même, cela ne servirait à rien, puisqu'à l'instant où ils seraient sortis de l'eau chaude, et posés sur une table de cuisine, ils ne sont plus stériles!

Ils doivent simplement être propres ; il suffit de les laver à l'eau tiède avec un produit ménager quelconque, les essuyer : ils sont ainsi prêts à être réutilisés. Une fois remplis, les bocaux seront stérilisés avec leur contenu.

Peut-on utiliser tout type de bocal ?

Oui, bien sûr à condition que ce soit un bocal destiné à la stérilisation ; il ne faut pas utiliser de bocaux réservés à la décoration pour un usage alimentaire. Si vous réutilisé un bocal, le joint (ou le cas échéant la capsule) doit être absolument neuf.

Doit-on faire bouillir les bocaux vides avant la stérilisation ?

Non ! C'est une idée fausse que l'on voit souvent sur internet. Il faut juste bien les laver. Vos bocaux et les joints doivent être propres et secs. Etant donné qu'une fois pleins, vous les ébouillanterez parfois même plus d'une heure, il est totalement inutile de les stériliser avant. Ils stériliseront en même temps que les aliments qu'ils contiennent !

Si vous stérilisez vos bocaux vides, votre environnement n'étant pas stérile (ni vos mains, ni votre cuisine, ni votre torchon), ce procédé n'aura servi à rien, car une recontamination sera alors immédiate. C'est une perte de temps et d'énergie.

Doit-on faire bouillir les joints des bocaux ?

Non, en principe, sauf indication précise du fabricant et qui doit figurer sur l'emballage. Dans le cas des joints Weck, ils sont en caoutchouc naturel et ne doivent pas être mis à bouillir avant stérilisation. Les joints ne sont pas réutilisables, tout comme les capsules, qui doivent être changés chaque stérilisation. Chaque marque de bocaux commercialisent les joints adaptés au bocal. Ainsi, les joints Weck ne vont QUE sur les bocaux Weck.

Si vous utilisez d'autres marques de bocaux telles que Mason, ou Le Parfait, référez-vous strictement aux règles préconisées par ces marques.

Peut-on réutiliser des bocaux ?

Bien sur ! On le peut à la condition de changer obligatoirement le joint ou la capsule, et que le bocal n'a ni impact, ni fissure.

Doit-on laisser refroidir les bocaux avec leur eau de stérilisation ?

Doit-on laisser refroidir les bocaux avec leur eau de stérilisation ?

NON, jamais ; c'est aussi une idée fausse ; le principe de la stérilisation consiste en une montée en température sans à-coup, un palier de stérilisation et un refroidissement rapide ; il faut donc sortir les bocaux de l'eau chaude immédiatement à la fin de la stérilisation et si possible les refroidir avec un jet d'eau fraîche ; plus vite ils seront refroidis, mieux ils se conserveront.

Si vous laissez vos bocaux refroidir dans l'eau, l y aura re-prolifération des bactéries dans l'eau.

Comment s'assurer qu'une conserve est réussie ?

Lorsque le bocal est refroidi, faire un test en essayant d'ouvrir le couvercle ; celui-ci doit opposer une résistance naturelle. Dans le cas des bocaux WECK, la languette penche naturellement vers le bas après stérilisation du bocal. Si la languette du joint remonte vers le haut, c'est que la stérilisation n'a pas réussie. Il faut donc conserver ce bocal au frigo et manger son contenu dans des délais très brefs.

Peut-on éviter le botulisme en utilisant un stérilisateur ménager ?

Évidemment ! Le botulisme est du à une bactérie qui est détruite à haute température (dès 80°/90°).

Si donc, vous appliquez rigoureusement les barèmes de stérilisation qui vous sont communiqués, vous n'aurez aucun problème.

Qu'est-ce que le botulisme et le Clostridium botulinum ?

Clostridium botulinum est une bactérie responsable du botulisme. Clostridium botulinum est une bactérie productrice de spores qui représentent la forme de résistance de la bactérie. Cette spore peut résister à de faibles traitements thermiques (ex : pasteurisation) et germer (c'est-à-dire donner une cellule métaboliquement active) ce qui peut poser des problèmes en sécurité alimentaire.

Il sécrète une des toxines les plus puissantes du monde animal. Active par ingestion, cette toxine diffuse ensuite dans l'organisme et agit en bloquant la transmission intermusculaire : elle inhibe les neurones moteurs de la contraction musculaire. On dit alors que la toxine provoque une paralysie généralisée flasque (contrairement à la toxine tétanique qui inhibe les neurones inhibiteurs de la contraction musculaire, induisant ainsi une paralysie généralisée spastique). cette infection peut entrainer la mort par paralysie des muscles respiratoires si aucun traitement n'est mis en place. Il existe trois formes de botulisme humain : le botulisme alimentaire (ingestion de la toxine pré-formée dans l'aliment), le botulisme infantile (colonisation de l'intestin par la bactérie) et le botulisme par blessure. L'intoxication fait souvent suite à la consommation de conserves ou de jambon et salaison « maison » mal stérilisés. La toxine est thermolabile et une simple cuisson à ébullition suffit à prévenir les risques.

La toxine résiste à l'acidité gastrique mais est thermolabile (détruite vers 80 à 90 °C) : il en résulte que si un aliment suspect est chauffé à ébullition juste avant d'être consommé, tout danger disparaît.

Nous vous mettons donc en garde contre les « conseils » donnés sur certains sites étrangers, essentiellement canadiens et américains, qui préconisent l'utilisation obligatoire d'une marmite pression autoclave pour échapper au botulisme ;

Ces appareils ne sont pas aux normes CEE, ni aux normes NF. Ainsi, vous restez responsables de l'achat et de leur utilisation. Si vous choisissez d'acquérir ce type de produits en dehors de la CEE, nous ne pouvons que vous inciter fortement à bien suivre les conseils et préconisations du fabriquant.

Pour ces raisons, MCM Emballages a choisit de ne pas commercialiser ce type d'appareils, préférant s'en tenir aux marques estampillées CEE.

Ces petits appareils de type Presto, ou All American sont d'un usage courant en Amérique du nord. N'hésitez pas à bien vous renseigner auprès du vendeur avant l'achat.

(Par définition, en France, un "autoclave" désigne un appareil réservé à l'usage industriel et professionnel. Les appellations et les normes varient selon les pays.)

Si vous souhaitez investir dans un appareil électrique équipé, un stérilisateur ménager Weck ou d'une autre marque est parfait ! Si vous faites peu de conserve, il n'est pas forcément utile d'investir dans ce type d'appareil. Pour la stérilisation domestique, vous n'avez besoin que d'un grand fait-tout et d'un thermomètre de cuisinier.

Comment bien se renseigner ?

En prenant contact avec nous au 03 88 55 17 75, ou à strasbourg@conservor.fr

Fiez vous aux professionnels dont la conserve est le métier depuis plus de 25 ans !

A bientôt.

L'équipe MCM Emballages

Doit-on laisser refroidir les bocaux avec leur eau de stérilisation ?

Doit-on laisser refroidir les bocaux avec leur eau de stérilisation ?